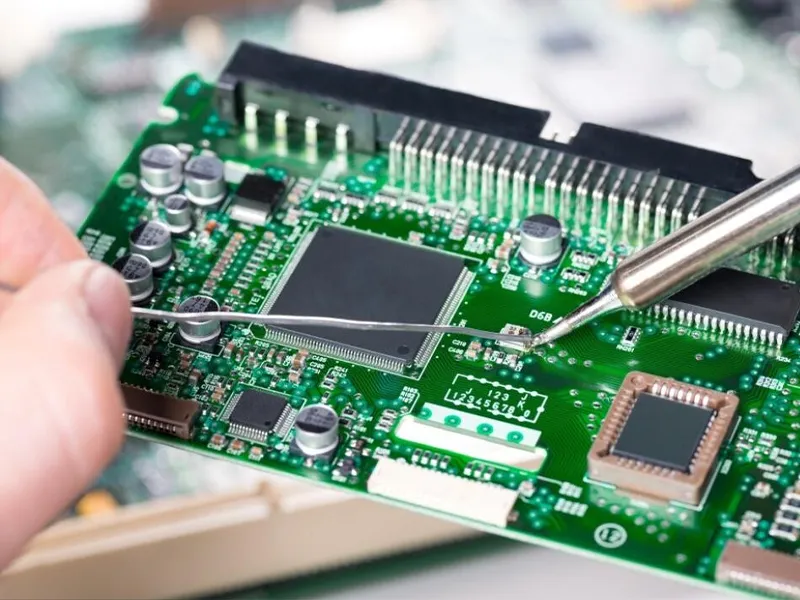

Professional Adhesive Tape Solutions for Electronics Manufacturing

KAWIN provides high-precision tapes for PCB masking, electrical insulation, thermal management, EMI/RFI shielding, and cleanroom assembly. Custom die-cut and OEM-equivalent options available for mass production and R&D.

Core Applications in Electronics

Our tapes are engineered for precision and reliability at each stage of electronics production — from PCB handling to final assembly.

PCB Masking & Protection

High-temperature masking tapes for wave-soldering and reflow processes that leave no residue and protect circuits during assembly.

Electrical Insulation

Polyimide (Kapton) and PET tapes for reliable dielectric strength and dimensional stability in tight tolerances.

Thermal Management

Thermally conductive tapes and aluminum foil tapes for heat dissipation in power modules and LED assemblies.

EMI / RFI Shielding

Conductive adhesive tapes for grounding, shielding and noise suppression in sensitive electronics.

Die-Cut Components

Precision die-cut gaskets, washers, and insulators for sensors, displays, and connector assemblies.

Cleanroom & SMT Handling

Low-residue specialty tapes suited for SMT pick-and-place and cleanroom processes.

Product Categories

| Type | Key Properties | Typical Uses |

|---|---|---|

| Polyimide (Kapton) Tape | High-temp, dielectric | PCB masking, wave/reflow soldering |

| PET Double-sided Tape | Thin, high shear | Component bonding, display assembly |

| Conductive Adhesive Tape | EMI shielding, grounding | Shielding, connector grounding |

| Thermally Conductive Tape | Heat transfer, gap filling | Power modules, LED cooling |

| Aluminum Foil Tape | Thermal & moisture barrier | Heat shielding, grounding |

| Cleanroom Low-Residue Tape | Residue-free, anti-static | SMT handling, cleanroom use |

Technical Specifications & Testing

KAWIN products undergo rigorous testing to ensure performance in demanding electronics environments.

Temperature Range

-50°C to +260°C (depending on product)

Dielectric Strength

Meets industry insulation requirements

Low Outgassing

Suitable for sealed electronic assemblies

Why Choose KAWIN

KAWIN = Performance + Reliability + Partnership“Engineered for Automotive Precision. Trusted by Professionals Worldwide.”

28+ Years of Expertise in Electronic Adhesives

With over 28 years of production and R&D experience, KAWIN specializes in high-performance adhesive tapes used in electronic manufacturing — from PCB insulation to lithium battery assembly.

Our engineers understand the precision, cleanliness, and temperature resistance requirements of today’s electronics production.

Full In-House Manufacturing & Strict Quality Control

All our products are manufactured in our ISO 9001 and IATF 16949 certified facilities.

From coating to slitting and testing, every process is completed in-house to guarantee consistent adhesive strength, dielectric performance, and dimensional stability — crucial for sensitive electronic applications.

OEM-Equivalent Tapes with Proven Reliability

KAWIN develops equivalent or alternative solutions to leading brands such as 3M, Tesa, and Nitto, providing the same or higher reliability at a more competitive cost.

Our tapes are rigorously tested for dielectric strength, thermal endurance, and low outgassing, ensuring compatibility with high-temperature and cleanroom processes.

Custom Engineering for Your Application

Different products need different properties — whether it’s insulation, EMI shielding, heat dissipation, or flame retardancy.

KAWIN’s R&D team can customize backing materials, adhesives, thickness, and width to meet your production requirements.

We support prototype-to-mass-production customization with short lead times.

Trusted by Global Electronics Manufacturers

Our tapes are used by OEMs and Tier 1 suppliers in PCB fabrication, EV battery production, consumer electronics, and semiconductor packaging.

We have established long-term partnerships in Asia, Europe, and North America, providing stable supply and consistent performance.

Reliable Support from Experts

At KAWIN, we don’t just sell tapes — we solve bonding challenges.

Our technical team provides on-site testing, sample verification, and performance reports, ensuring that your chosen product works seamlessly within your process line.

Request Samples or a Technical Consultation

Tell us your application details—our engineers will recommend a tape within 24 hours.