Product Highlights

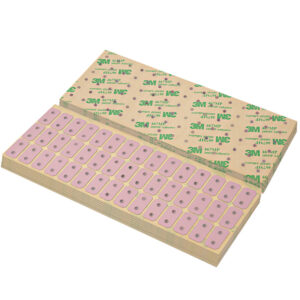

This tape uses an acrylic bonding formulation reinforced with a thin dielectric film. The adhesive surface forms intimate contact with metal, ceramic or PCB substrates, helping remove heat from active components while keeping electrical insulation between layers. It is commonly used to attach heat sinks or housings to devices that generate significant heat during operation.

Key Features

Double-sided pressure-sensitive adhesive

Thermal conduction and electrical insulation in a single material

No curing or mechanical fastening required

Stable adhesion on metals, PCBs and coated surfaces

Allows thin assembly design for compact electronics

Suitable for continuous operating temperatures from approximately -30°C to 120°C (depending on grade)

UL 94 V-0 flame retardant rating on many variants

Typical Technical Values (reference only)

Construction: double-sided acrylic PSA with dielectric carrier (PEN or polyimide film)

Thickness: around 0.14 mm (varies with product grade)

Thermal conductivity: around 0.4 W/m·K

Thermal impedance at 50 psi: approx. 0.87 °C-in²/W

Performance varies depending on applied pressure, substrate type and surface flatness and should be validated in each application.

Recommended Applications

Bonding heat sinks to PCB modules or power devices

LED lighting modules and aluminum housings

Automotive control units requiring insulation plus heat dissipation

Power electronics where mechanical fasteners are difficult or space-limited

Replacement for silicone grease or liquid adhesive in many low-profile heat paths

Why Engineers Choose Bergquist Tape

Bergquist tape is widely used in demanding OEM environments because it combines thermal interface performance, stable adhesion and dielectric insulation without converting processes. For large-scale production, the tape simplifies assembly and improves repeatability compared with liquid or mechanical options.

Available Formats

Continuous roll, sheet, kiss-cut, die-cut pads and custom-shaped parts for OEM assembly. Dimensions can be customized based on heat sink size or component layout.

Ordering Information

To recommend the correct grade, please confirm:

component material and substrate

required operating temperature

electrical insulation requirement

target thermal impedance

thickness preference

standard or custom die-cut shape

Reviews

There are no reviews yet.