Product Highlights

High thermal conductivity and electrical insulation in one tape

Double-sided pressure-sensitive adhesive for easy application

Fiberglass carrier provides excellent mechanical strength and heat resistance

Ideal for thin, compact assemblies where screws, clips, or thermal epoxies are not practical

Stable adhesion on metals, ceramics, PCBs, and coated surfaces

Continuous operating temperature typically from -30°C to 150°C (depending on grade)

Key Features

Thermal management: Efficiently transfers heat from CPUs, power modules, LEDs, and other heat-generating components to heat sinks, metal housings, or other thermal paths

Mechanical bonding: Eliminates or reduces the need for mechanical fasteners, allowing lighter and thinner assemblies

Electrical insulation: The fiberglass carrier and adhesive provide dielectric isolation where required

Industrial reliability: High tear and tensile strength from fiberglass carrier ensures long-term performance in harsh environments

Easy application: No curing required; press tape between surfaces and it adheres immediately

Typical Technical Values (for reference)

Tape construction: Double-sided adhesive with fiberglass cloth carrier

Thickness: 0.1–0.2 mm depending on product variant

Thermal conductivity: 0.4–0.8 W/m·K (depends on adhesive type)

Thermal impedance: Approx. 0.8–1.2 °C·in²/W at 50 psi

Operating temperature range: -30°C to 150°C

Electrical insulation: Dielectric carrier ensures isolation

Performance depends on substrate type, surface flatness, applied pressure, and environmental conditions. Testing under real application conditions is recommended.

Typical Applications

Mounting heat sinks to PCBs, power modules, or LEDs

Bonding LED modules or aluminum housings in lighting fixtures

Thermal management in automotive modules and power electronics

Compact assemblies where mechanical fasteners are impractical

Replacement for silicone grease or liquid adhesives in low-profile thermal interfaces

Why Choose Fiberglass Thermal Tape

Fiberglass thermal tape combines mechanical adhesion, thermal conductivity, and electrical insulation in a single, easy-to-use product. It improves assembly efficiency, reduces the number of components, and delivers stable thermal performance over time. Ideal for OEM production and industrial applications where reliability and compact design are critical.

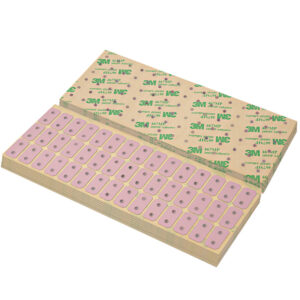

Available Formats

Rolls, sheets, die-cut pads, or custom shapes for OEM assemblies

Widths, lengths, and thicknesses can be customized to meet specific thermal and mechanical requirements

Ordering Considerations

To select the correct variant, specify:

Substrate materials (metal, PCB, plastic)

Operating temperature range

Thermal conductivity requirements

Electrical insulation requirements

Tape dimensions and format

This information allows choosing the right adhesive type and fiberglass carrier thickness to optimize thermal performance and mechanical bonding.

Reviews

There are no reviews yet.