Customer Background

A consumer electronics manufacturer in Vietnam produces smart home devices and handheld electronic products for export to the US and European markets.

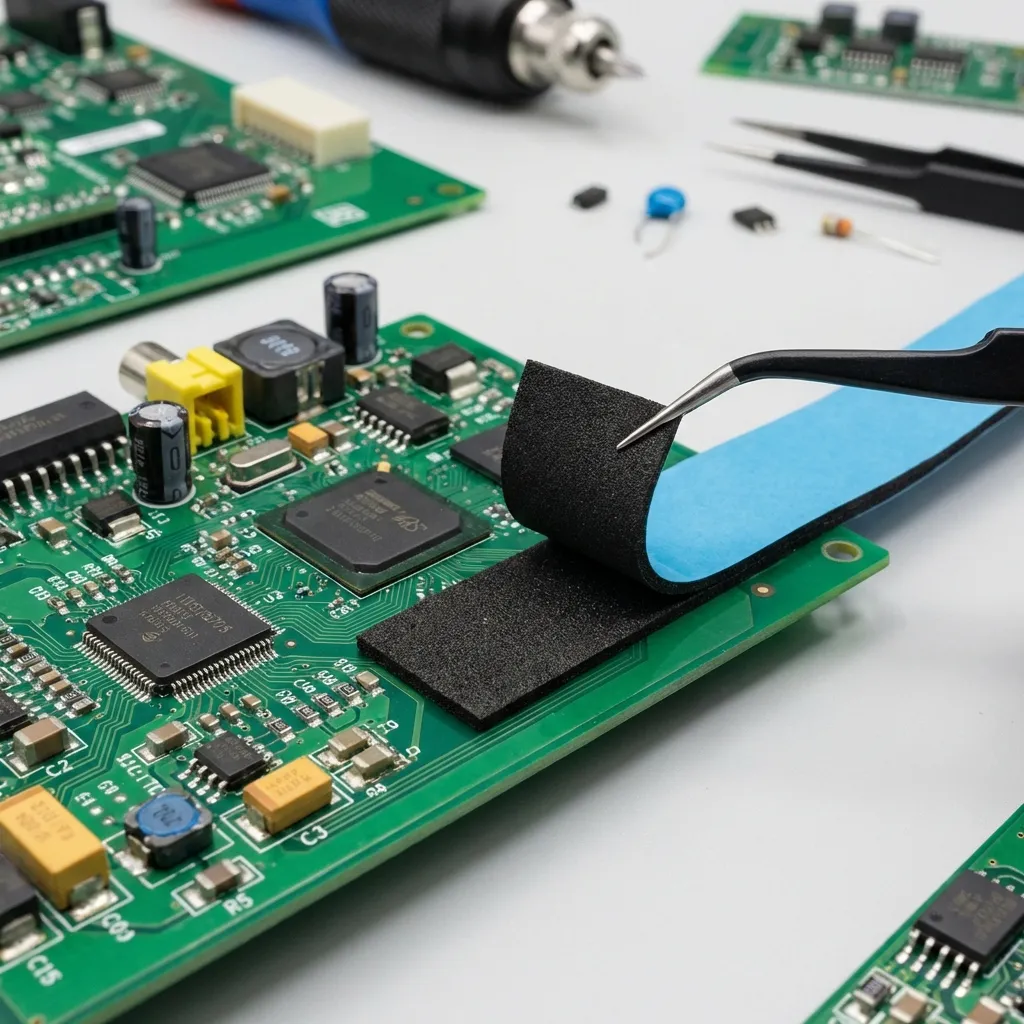

They required a reliable foam tape solution for internal component protection during assembly and transportation.

Typical applications included:

PCB cushioning

Display module support

Connector and sensor protection

Challenge: Drop Damage and Internal Component Movement

The customer experienced frequent issues during product testing and shipping:

Internal components shifting after drop tests

Insufficient cushioning around PCB and display modules

Adhesive failure on plastic housings

Increased return rates due to transit damage

They needed a foam tape that could provide shock absorption without adding excessive thickness.

Solution Provided: High-Density PE Foam Tape for Electronics

We supplied a high-density PE foam tape optimized for electronic device assembly.

Product Specifications

Foam type: High-density PE foam

Thickness: 1.5mm

Adhesive: Acrylic pressure-sensitive adhesive

Compression recovery: Excellent

Compatible surfaces: ABS, PC plastics, aluminum frames

Available supply formats:

Narrow slit rolls for manual assembly

Die-cut foam pads for automated placement

Custom thickness options for different device designs

Results Achieved After Product Testing

| Performance Metric | Improvement |

|---|---|

| Drop-test failure rate | ↓ 38% |

| Internal component movement | Significantly reduced |

| Assembly consistency | ↑ 20% |

| Product return rate | ↓ 25% |

The foam tape provided reliable cushioning while maintaining compact internal spacing.

Why Foam Tape is Widely Used in Electronics Assembly

Foam tape helps electronics manufacturers by:

Absorbing impact energy during drops

Preventing friction between components

Improving structural stability inside housings

Supporting long-term device reliability

Common applications include:

PCB spacing and protection

Display cushioning

Speaker and sensor mounting

Cable management

FAQ

What foam tape is best for electronics shock absorption?

High-density PE foam tape is commonly used for electronics cushioning because it offers good compression recovery and lightweight shock absorption.

Can foam tape be supplied in die-cut shapes for electronics assembly?

Yes. Die-cut foam tape parts allow precise placement and faster assembly in electronic device production lines.

Will foam tape leave residue on electronic components?

High-quality acrylic adhesive foam tapes are designed for clean application and stable adhesion without residue during the product lifecycle.