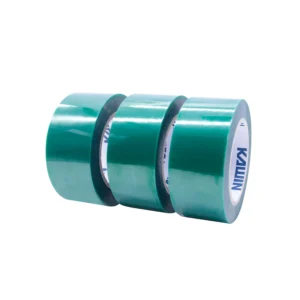

Industrial-grade high-temperature tape

Types of High Temperature Tape

High temperature tape is a type of industrial adhesive tape engineered to maintain adhesion, insulation performance, and mechanical stability under continuous exposure to elevated temperatures. It is essential in manufacturing processes involving heat, electrical insulation, and surface protection.

Key Features

- Continuous temperature resistance up to 260°C (500°F)

- Excellent electrical insulation performance

- Strong adhesion with clean removal

- Designed for industrial manufacturing environments

- Custom widths, thicknesses, and adhesive systems available

Industrial Applications

- PCB masking and wave soldering

- Powder coating and high-temperature painting

- Automotive wire harness insulation

- Electrical and thermal insulation systems

- Battery and electronics manufacturing

Why Choose Our High Temperature Tape

As an experienced industrial tape manufacturer, we provide reliable high temperature tape solutions designed for demanding B2B applications.

Our advantages include:

Stable adhesion under high heat

Clean removal with minimal residue

Consistent quality and batch stability

Custom widths, lengths, and adhesive systems

OEM and private label manufacturing support

Competitive factory-direct pricing

Our products are designed to meet the performance expectations of global industrial customers.

High Temperature Tape FAQs

Depending on the material and adhesive system:

Polyimide (Kapton®-type) tape: up to 260°C (500°F) short-term

Fiberglass tape: up to 260–300°C (500–572°F)

PTFE (Teflon®) tape: up to 260°C (500°F)

Please refer to the technical datasheet for continuous vs. short-term temperature ratings.

We supply a full range of industrial high temperature tapes, including:

Polyimide (Kapton-type) tape

Fiberglass tape

PTFE tape

Aluminum foil high temperature tape

Silicone adhesive high temperature tape

Custom widths, lengths, and adhesive systems are available.

Yes. As a manufacturer, we support:

Custom widths, lengths, and thicknesses

Jumbo rolls or die-cut parts

OEM & private label production

Minimum order quantities may apply depending on specifications.

Our products can comply with relevant standards such as:

RoHS

REACH

UL (for selected models)

Compliance documentation is available upon request.

Key selection factors include:

Maximum operating temperature

Substrate material

Required adhesion strength

Electrical insulation needs

Removal requirements

Our technical team can help recommend the most suitable tape for your application.

Yes. Samples are available for qualified B2B customers to validate performance before bulk orders.