Why 200MP adhesive

3M’s 200MP adhesive is recognized in the industry for:

outstanding shear strength

excellent high-temperature stability

high bonding strength on metals and HSE plastics

resistance to chemicals and solvents

minimal edge lifting and long-term holding power

This adhesive system is frequently selected by engineers where long-term reliability is required.

Key Performance Advantages

Strong permanent bonding on aluminum, stainless steel, copper, PET, PC, and other high-surface-energy plastics

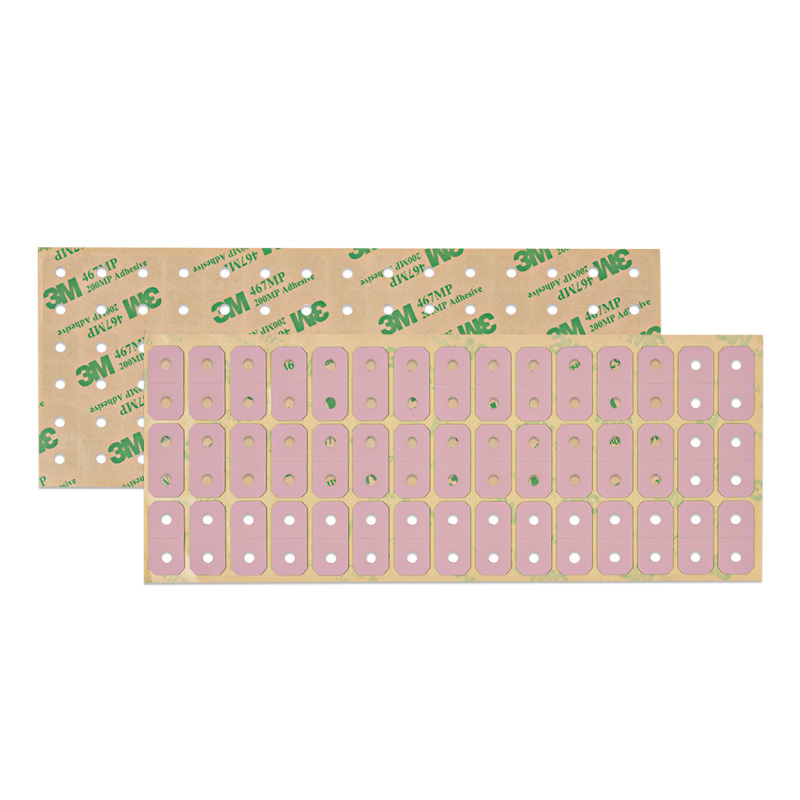

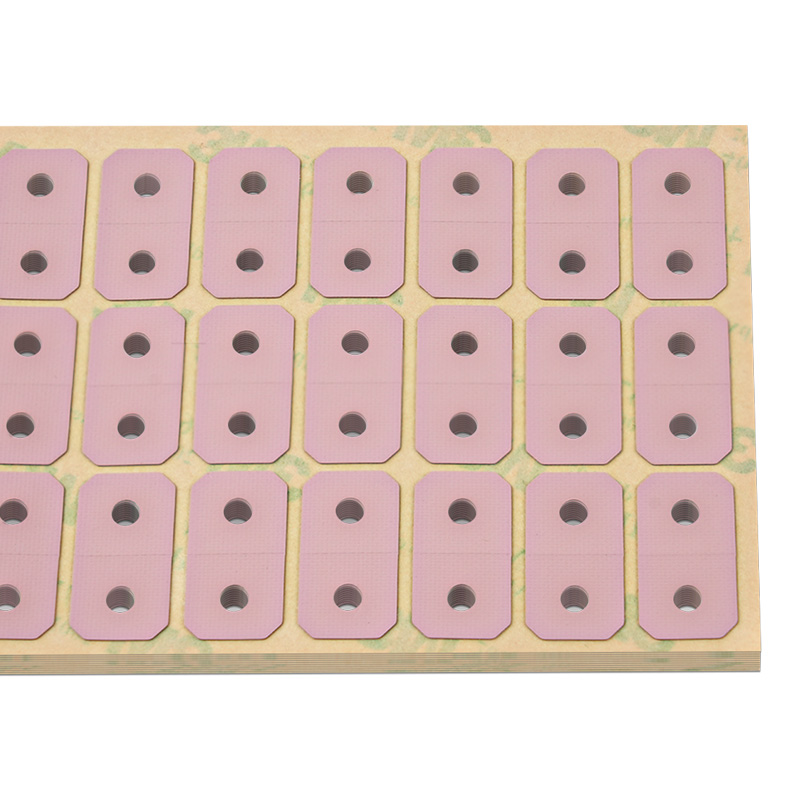

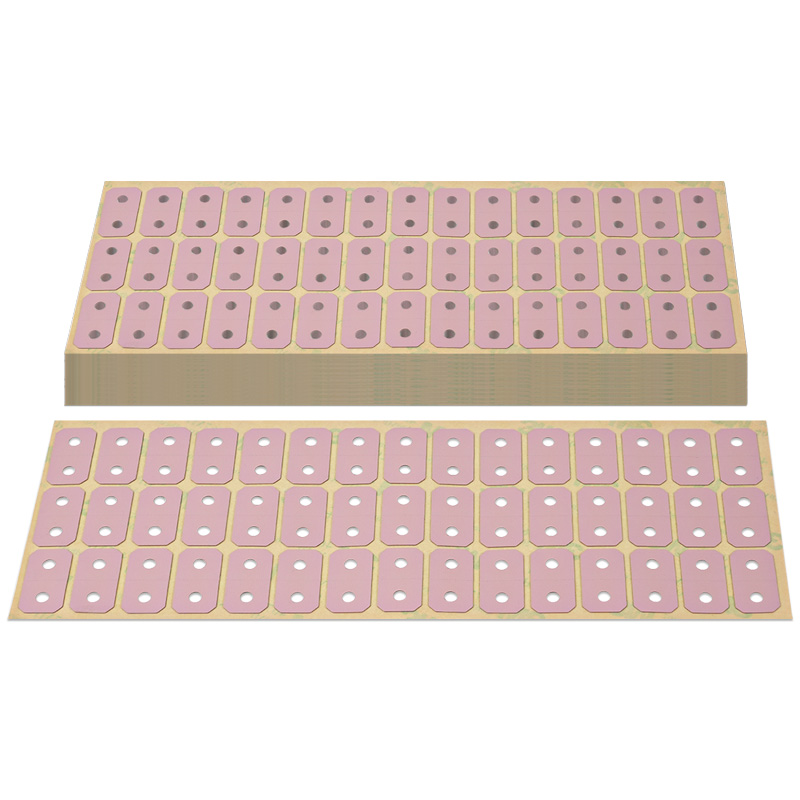

Excellent die-cutting and lamination performance

Thin profile for precise bonding of overlays and graphic layers

Outstanding shear and peel strength

High consistency suitable for automated assembly lines

Good dimensional stability over time

Designed for industrial OEM environments

Typical Technical Data (representative values)

| Property | Value |

|---|---|

| Adhesive Type | Acrylic (3M 200MP) |

| Tape Thickness (without liner) | ~0.06 mm (2.3 mil) |

| Liner | 58# PCK (Poly-coated kraft paper) |

| 180° Peel (Steel) | ~77 oz/in (typical) |

| Shear Strength | High (suitable for heavy load bearings) |

| Temperature Resistance | Short-term up to ~204°C (400°F) |

| Humidity / Solvent Resistance | Excellent |

| Die-cutting | Suitable for rotary and flat die-cutting |

Testing under real production conditions is recommended, especially where high temperature, solvents or chemical exposure are involved.

Industry Applications

Designed for:

Nameplates, rating plates, identification plates

Graphic overlays and membrane switch assemblies

Control panels and display overlays

High-surface-energy plastic bonding

Metal bonding (Al, SS, Cu, etc.)

Electronics and appliance components

Lamination of metal foil layers

Common in automotive, appliance, instrumentation, medical device housings, industrial equipment, and electronic assembly applications.

Engineering Benefits

Consistent thickness for laminated stack designs

Strong holding power even on vertical or loaded structures

Low stretch adhesive transfer film

Long service life under temperature cycling

Clean and precise bonding for finished surfaces

Compatible with die-cut converters and automated lamination

For OEM & Industrial Buyers

We support:

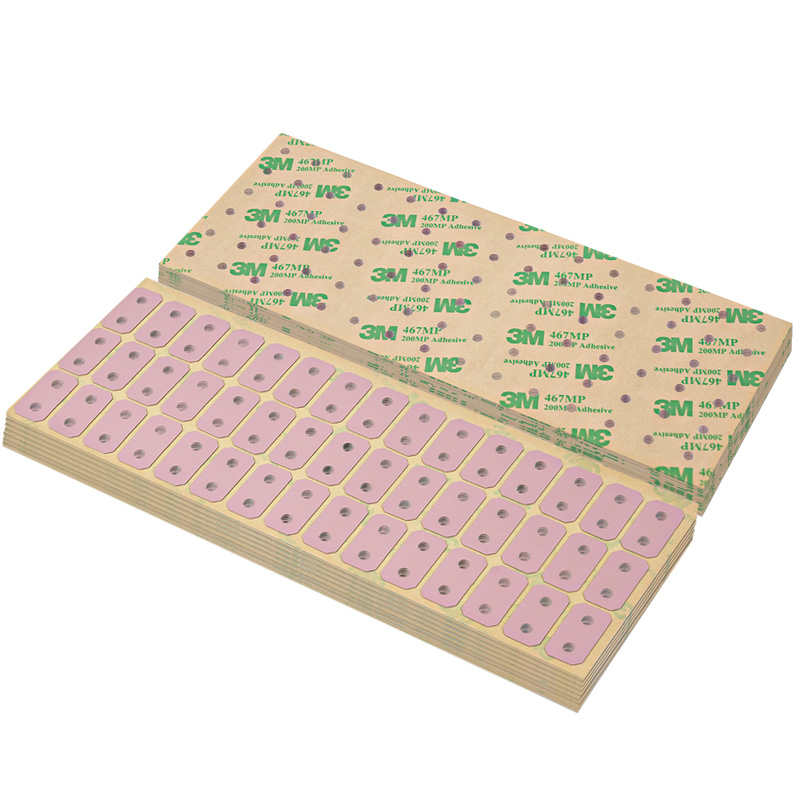

OEM bulk supply

die-cut formats

slit rolls

industrial packaging

application recommendations based on substrate type

technical guidance for temperature, solvent and aging conditions

Why engineers choose 467MP

This product has become a “reference material” in industrial bonding because it offers:

a proven adhesive system

long-term field reliability

precise performance data

predictable bonding behavior

stable adhesion in harsh environments

Engineers, R&D departments and purchasing managers frequently specify 467MP due to its long history, documentation availability and globally recognized performance standard.

Request datasheet & application recommendation

Share your application (substrate, temperature requirement and bonding area) and we will recommend the most suitable configuration and provide technical data for evaluation.

Reviews

There are no reviews yet.