Key Benefits of Heat Anti-Stick Protective Film

High-Temperature Resistance

The film retains its integrity and protective properties at elevated temperatures, typically up to 120°C–150°C, depending on specification.Reduced Adhesion for Clean Removal

Specially formulated low-tack adhesive prevents sticking and residue formation during and after heat exposure.Durable and Flexible

Resistant to tearing, punctures, and abrasion, the film conforms to irregular or textured surfaces without compromising protection.Multi-Surface Compatibility

Ideal for metals, painted surfaces, plastics, composites, laminates, and coated materials.

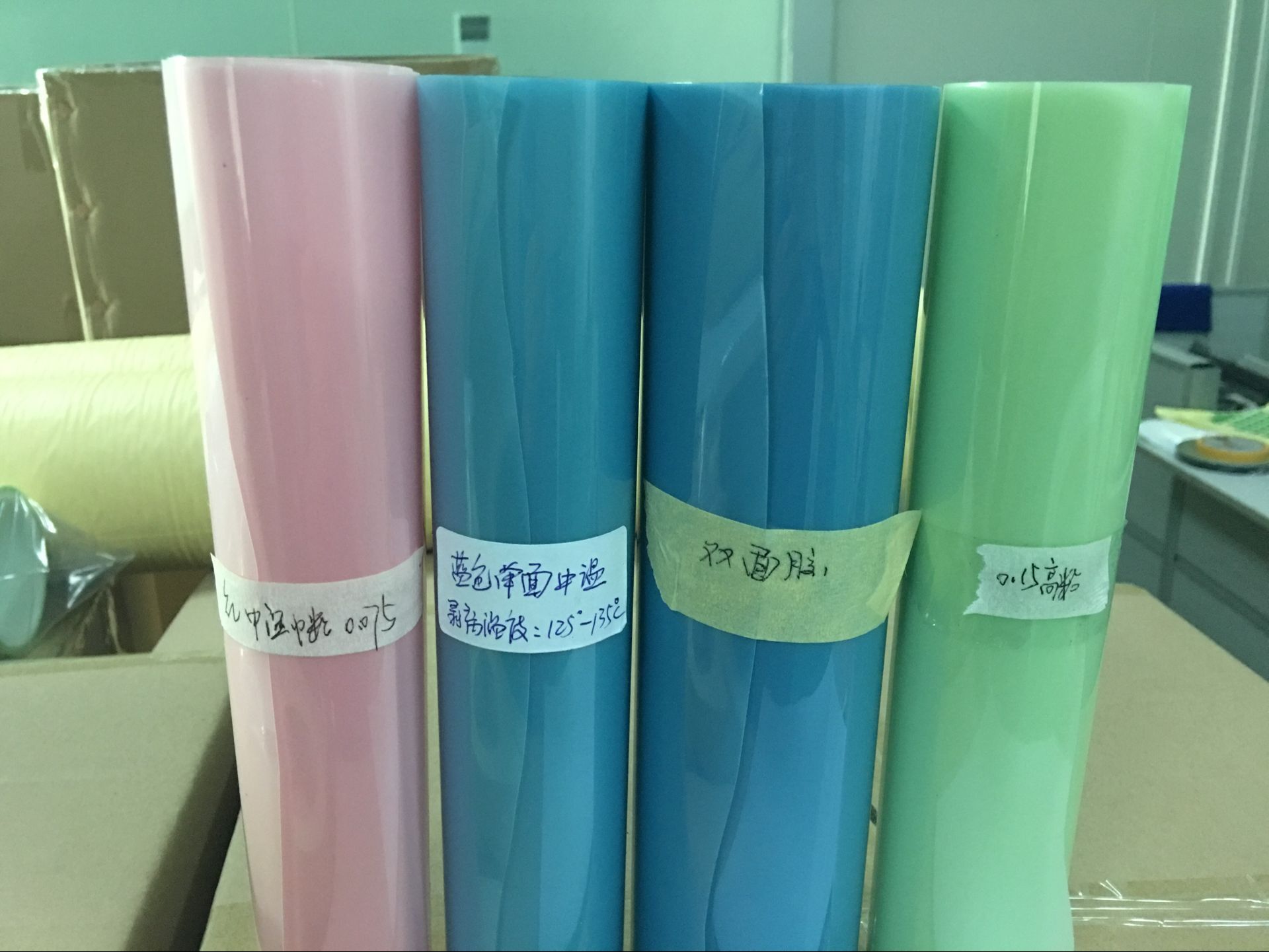

Technical Specifications

| Feature | Detail |

|---|---|

| Material | High-grade PU/PE with heat-resistant additives |

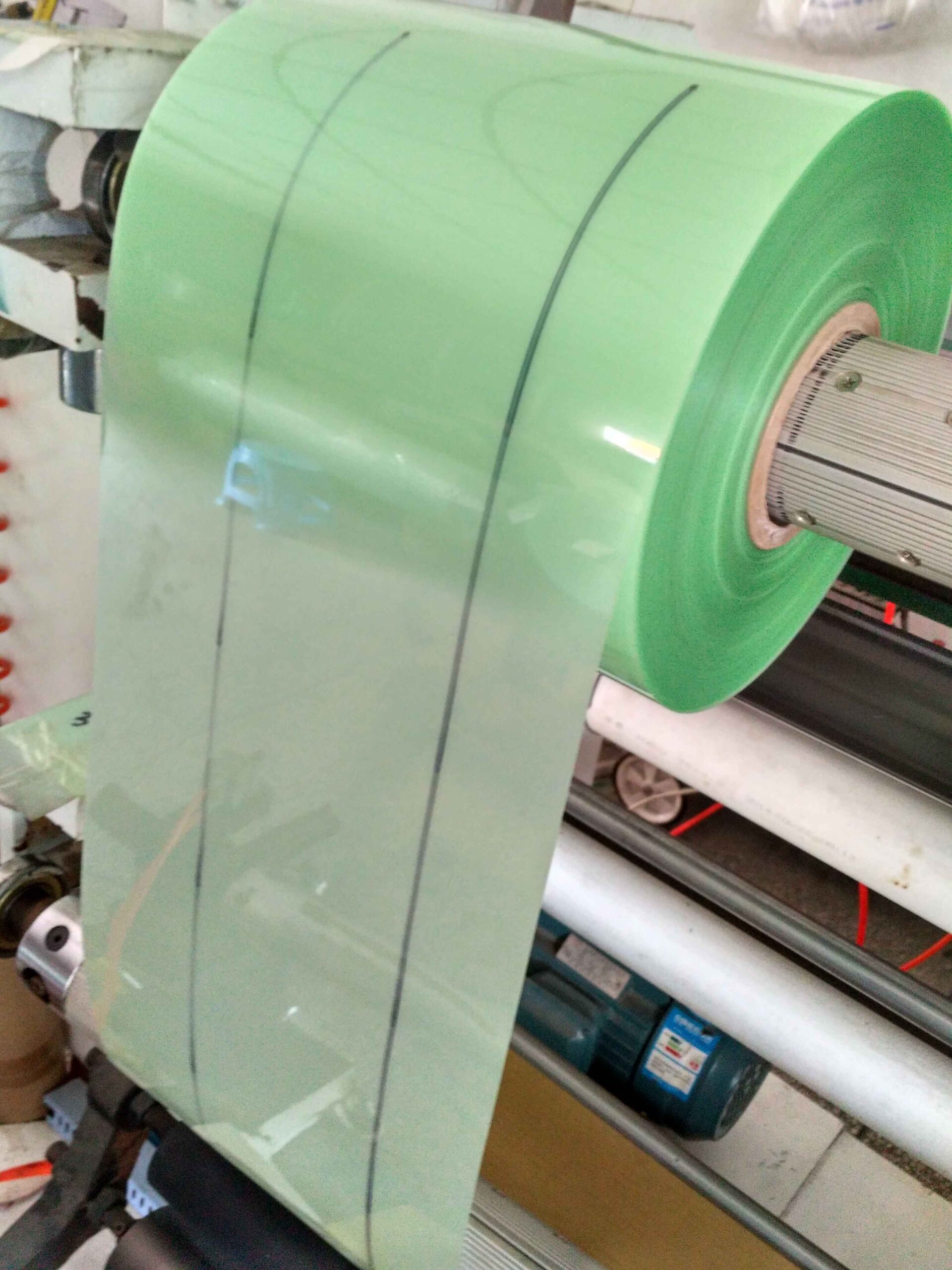

| Thickness | 30–200 μm |

| Width | 100–2000 mm (customizable) |

| Length | 50–1000 m per roll |

| Adhesive | Low-residue, heat-stable |

| Temperature Range | Up to 150°C (depends on specification) |

| Surface | Smooth / Matte options available |

Specifications can be customized based on industrial requirements.

Real-World Applications

Electronics Manufacturing: Protects screens, housings, and sensitive components during soldering or hot-press processes.

Automotive & Aerospace: Shields painted and coated parts during heat curing, thermoforming, and assembly.

Plastic & Composite Fabrication: Prevents surface sticking during thermoforming, laminating, or hot embossing.

Industrial & Household Appliances: Protects metal and plastic surfaces in processes involving heat or hot assembly.

Why Professionals Trust Our Heat Anti-Stick Film

Materials Expertise: Developed with polymer and adhesive engineers for optimal heat resistance and clean peel.

Performance Validation: Tested under high-temperature conditions to ensure adhesion stability and residue-free removal.

Custom Solutions: Thickness, adhesive strength, width, and surface finish tailored to client-specific applications.

Global Adoption: Used by manufacturers worldwide for high-value, heat-processed products.

Ordering & Customization

MOQ: Flexible, starting from 500 rolls.

Customization: Tailored thickness, adhesive, and film type for each application.

Delivery: Fast production with international shipping capabilities.

Conclusion

For heat-intensive manufacturing processes, ordinary protective films are insufficient. Our heat anti-stick protective film ensures surface protection, clean removal, and temperature stability, giving manufacturers confidence that their products remain flawless from production to delivery.

Request a sample or contact us to discuss a custom solution for your specific application.

Reviews

There are no reviews yet.