Product Highlights

High thermal conductivity for effective heat dissipation

Electrically insulating, safe for sensitive electronic components

Soft, conformable silicone material ensures intimate contact and fills surface gaps

Suitable for use in compact and space-limited assemblies

Stable performance across wide temperature ranges, typically -40°C to 200°C

Available in various thicknesses, densities, and sizes for customized applications

Key Features

Gap filling & thermal management: Pads fill surface irregularities to reduce thermal resistance and improve heat transfer efficiency

Electrical insulation: Provides dielectric isolation while transferring heat

Flexible & conformable: Can accommodate uneven or textured surfaces for consistent thermal contact

Durable: Resistant to aging, moisture, and common chemicals; maintains performance under thermal cycling

Easy to apply: Can be cut, die-cut, or custom-shaped to fit component layouts without adhesives if required

Typical Technical Values (for reference)

Material: Silicone elastomer with thermally conductive fillers

Thermal conductivity: 1.0–6.0 W/m·K (depends on grade)

Thickness: 0.25–5 mm (customizable)

Hardness (Shore A): 40–70

Operating temperature range: -40°C to 200°C

Electrical insulation: >10^12 Ω·cm

Flame retardant rating: UL 94 V-0 for many grades

Performance depends on pad thickness, applied pressure, surface flatness, and environmental conditions. Testing in real application conditions is recommended.

Typical Applications

Heat transfer from CPUs, GPUs, power modules, LEDs to heat sinks or metal housings

Thermal interface material in automotive electronics, power supplies, and industrial modules

Replacement for thermal grease or gap filler in low-profile assemblies

Situations where electrical insulation is required along with heat conduction

Why Choose Thermal Silicone Pads

Thermal silicone pads combine high thermal conductivity, electrical insulation, and gap-filling properties in a single, ready-to-use material. They simplify assembly, reduce the need for messy thermal pastes or adhesives, and provide stable, long-term thermal performance in demanding industrial applications.

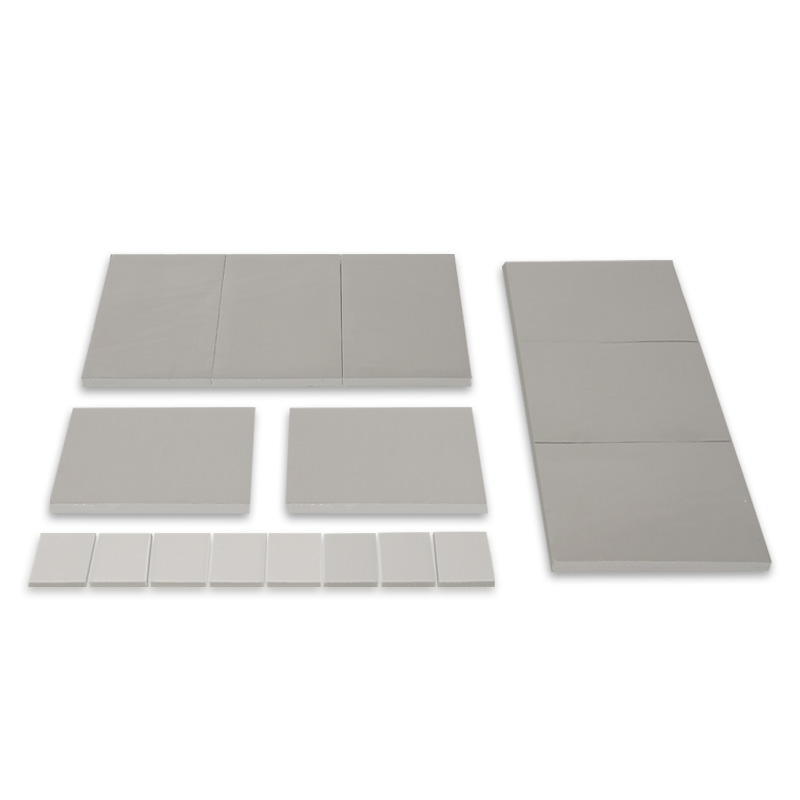

Available Formats

Sheets, rolls, die-cut pads, or custom shapes

Thickness, size, and thermal conductivity can be customized according to the component layout and thermal requirements

Ordering Considerations

When selecting a thermal silicone pad, specify:

Required thickness and dimensions

Target thermal conductivity

Operating temperature range

Electrical insulation requirement

Whether adhesive backing is needed or not

This ensures the pad meets both thermal and mechanical requirements for your application.

Reviews

There are no reviews yet.