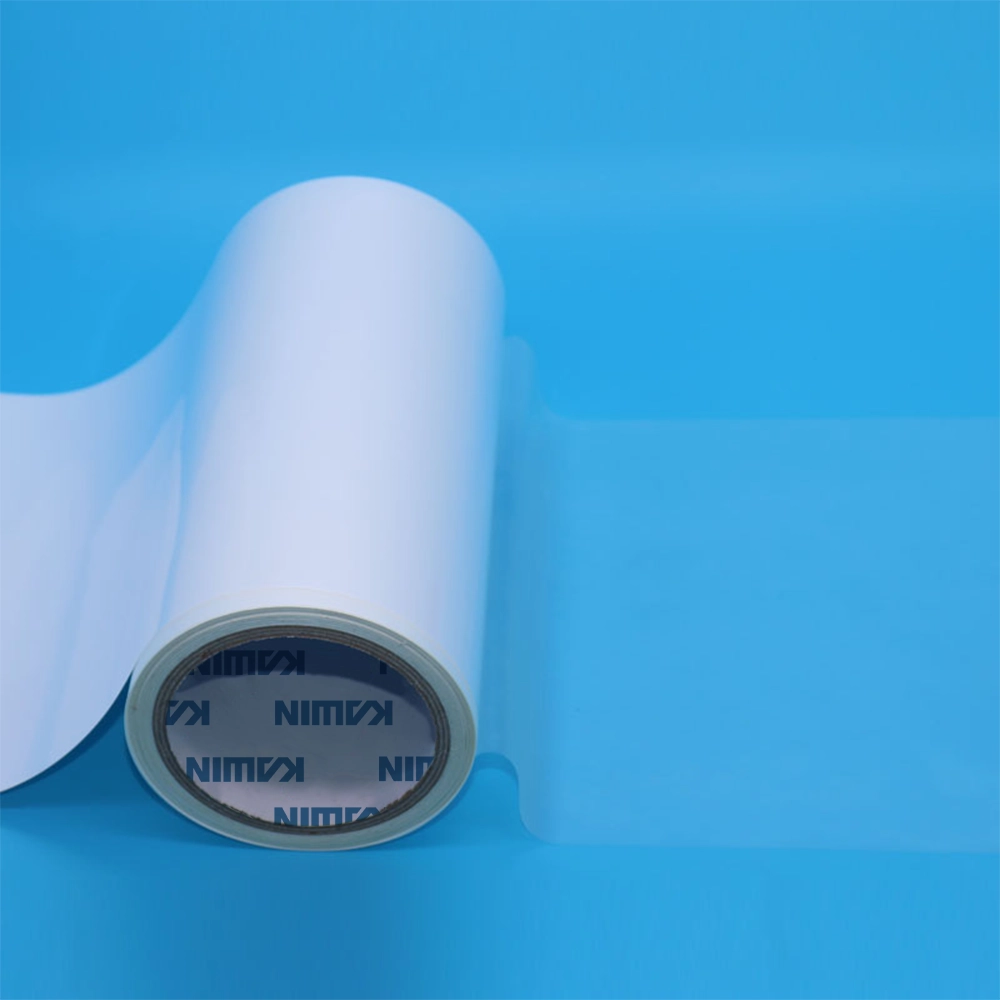

Product Overview

Hot melt adhesive film is a solid bonding material that becomes tacky and adhesive when heated. Unlike liquid glues, it provides clean, precise, and efficient bonding without mess, making it ideal for industrial-scale applications.

Key Features & Benefits

Strong Adhesion – Ensures reliable bonding to fabrics, plastics, metals, and composites.

Heat-Activated – Bonds firmly when processed under heat and pressure.

Clean & Eco-Friendly – Solvent-free, odorless, and safe for workers and the environment.

Customizable Options – Available in different thicknesses, widths, and roll sizes to suit production needs.

Durable Performance – Resistant to aging, moisture, and environmental stress.

Product Specifications

Product Code | Color | Total Thickness [um] | Backing | Adhesive | Initial Tack[mm] | 180°Peel Strength [N/inch] | Retentivity [hour] | Long-Term Temperature Resistance [℃] | Short-Term Temperature Resistance [℃] |

| KN3100HM | Translucent/Yellow | 60-140 | Tissue | hot melt glue | winter≤200 summer≤100 | winter≥6-20 summer≥8-15 | winter≥0.5-3 summer≥1-6 | 30 | 40 |

| Storage and shelf life | It is recommended to store in a clean and dry place, away from direct sunlight to prevent damage to the packaging, and to avoid storing with volatile solvents. Store at 25±5°C and humidity at 50±5%. | ||||||||

Applications

Textiles & Garments – Seam sealing, embroidery backing, and fabric lamination.

Footwear Industry – Shoe sole bonding, upper reinforcement, and decorative lamination.

Automotive Interiors – Trim attachment, insulation, and soundproofing.

Electronics – Flexible circuit assembly, insulation layers, and protective bonding.

Why Choose Our Hot Melt Adhesive Film?

Our adhesive films are engineered for high performance and ease of processing, helping manufacturers reduce production costs, improve product durability, and achieve clean, eco-friendly bonding solutions across multiple industries.

Reviews

There are no reviews yet.