At the cutting edge of battery technology, where higher energy density and faster charging speeds are paramount, traditional copper foil faces challenges like high interfacial impedance and insufficient electrochemical stability. Our Nano Carbon Copper Foil is a revolutionary material born to solve these bottlenecks. While inheriting copper foil’s ultra-high conductivity, it uses advanced nano carbon coating technology to imbue the material with new properties: it is not only an efficient electrode current collector but also a precise thermal management medium and a guardian of long-term battery stability.

Core Advantages & Key Features

- Dual Conductivity for Ultimate Performance The perfect combination of the nano carbon coating and copper foil creates a dual-conductive network. This significantly reduces the interfacial resistance between the electrode and the current collector, ensuring rapid electron transfer. It elevates the battery’s charge-discharge rate and cycle efficiency, providing a solid foundation for high-power applications.

- Superior Electrochemical Stability for a Long Cycle Life The nano carbon coating forms a dense protective layer on the copper foil’s surface, effectively suppressing copper oxidation and side reactions, especially in high-voltage operating environments. This not only reduces battery self-discharge and capacity fade but also extends the battery’s overall cycle life, lowering long-term usage costs.

- Passive Thermal Management to Prevent Thermal Runaway Unlike traditional cooling methods, the nano carbon coating’s high far-infrared emissivity allows it to efficiently and uniformly radiate heat generated inside the battery. This passive thermal management mechanism effectively lowers battery temperature rise, prevents localized hot spots, and fundamentally averts the risk of thermal runaway, enhancing battery safety.

- Enhanced Electrode Adhesion & Flexibility The coating material has excellent adhesive compatibility with electrode active materials, significantly improving adhesion and preventing electrode peeling. At the same time, the nano carbon copper foil maintains superb flexibility, allowing it to perfectly adapt to various battery structures and manufacturing processes.

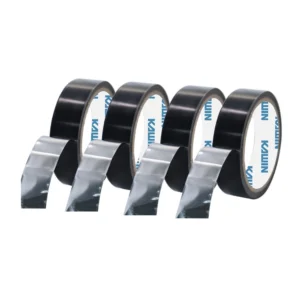

Technical Specifications

| Product Code Technical Parameters | KN1503 | KN1505 | KN1506 | KN1508 | KN1510 | KN1511 | KN1512 | KN1515 |

| Color | Black | Black | Black | Black | Black | Black | Black | Black |

| Total Thickness[mm] | 0.03 | 0.05 | 0.06 | 0.08 | 0.1 | 0.11 | 0.12 | 0.15 |

| Backing Thickness[mm] | 0.009 | 0.02 | 0.03 | 0.035 | 0.05 | 0.07 | 0.07 | 0.07 |

| Backing | Nano Carbon Copper Foil | |||||||

| Adhesive | Acrylic | |||||||

| 180°Peel Strength[N/inch] | 10 | 10 | 12 | 12 | 12 | 12 | 12 | 12 |

| Initial Adhesion[#] | 2 | 2 | 3 | 3 | 3 | 3 | 3 | 3 |

| Retentivity [hour] | 48 | |||||||

| Long-Term Temperature Resistance[℃] | 80 | |||||||

| Short-Term Temperature Resistance[℃] | 120 | |||||||

| Surface Resistance[mΩ] | 50 | |||||||

| Base Thermal Conductivity[W/mk] | 400 | |||||||

| Composite Thermal Conduction Coefficient [W/mk] | 600-800 | |||||||

Typical Applications

- New Energy Vehicle Power Batteries: As a negative electrode current collector for high-power, high energy-density batteries, improving fast-charging performance and safety.

- Energy Storage Systems: For use in large-scale energy storage plants to extend battery lifespan and reduce maintenance costs.

- High-End Consumer Electronics: As an efficient passive heat dissipation material and electrode material in smartphones and laptops.

- Specialized Electronic Devices: For niche applications that require high conductivity, high thermal stability, and lightweight materials.

Client Testimonials & Case Studies

“We’ve been searching for a current collector that could simultaneously enhance battery power, lifespan, and safety. Traditional copper foil’s performance would degrade after many cycles. This nano carbon copper foil has completely changed our design approach. It maintains extremely low resistance and stable performance even after thousands of cycles, laying the foundation for the successful development of our next-generation power batteries.” — R&D Director, a leading EV battery manufacturer

Frequently Asked Questions (FAQ)

- Q: What’s the difference between nano carbon copper foil and nano carbon aluminum foil in terms of application? A: Copper foil is more conductive than aluminum and is the standard current collector for lithium-ion battery anodes. Nano carbon copper foil is primarily used for the anode, where conductivity and electrochemical stability are critical. Nano carbon aluminum foil is mainly used for the cathode or as a general-purpose thermal management material.

- Q: How does it achieve passive thermal management? A: The high far-infrared emissivity of the nano carbon coating allows it to dissipate heat efficiently via radiation. It acts like a “black body,” rapidly “radiating” heat from the battery’s interior to the external environment, thereby preventing heat buildup.

- Q: What about the cost of this material? A: While slightly more expensive than traditional copper foil, considering the significant improvements in battery performance, lifespan, and safety, as well as the potential reduction in maintenance and replacement costs, the long-term return on investment is very high.

Reviews

There are no reviews yet.