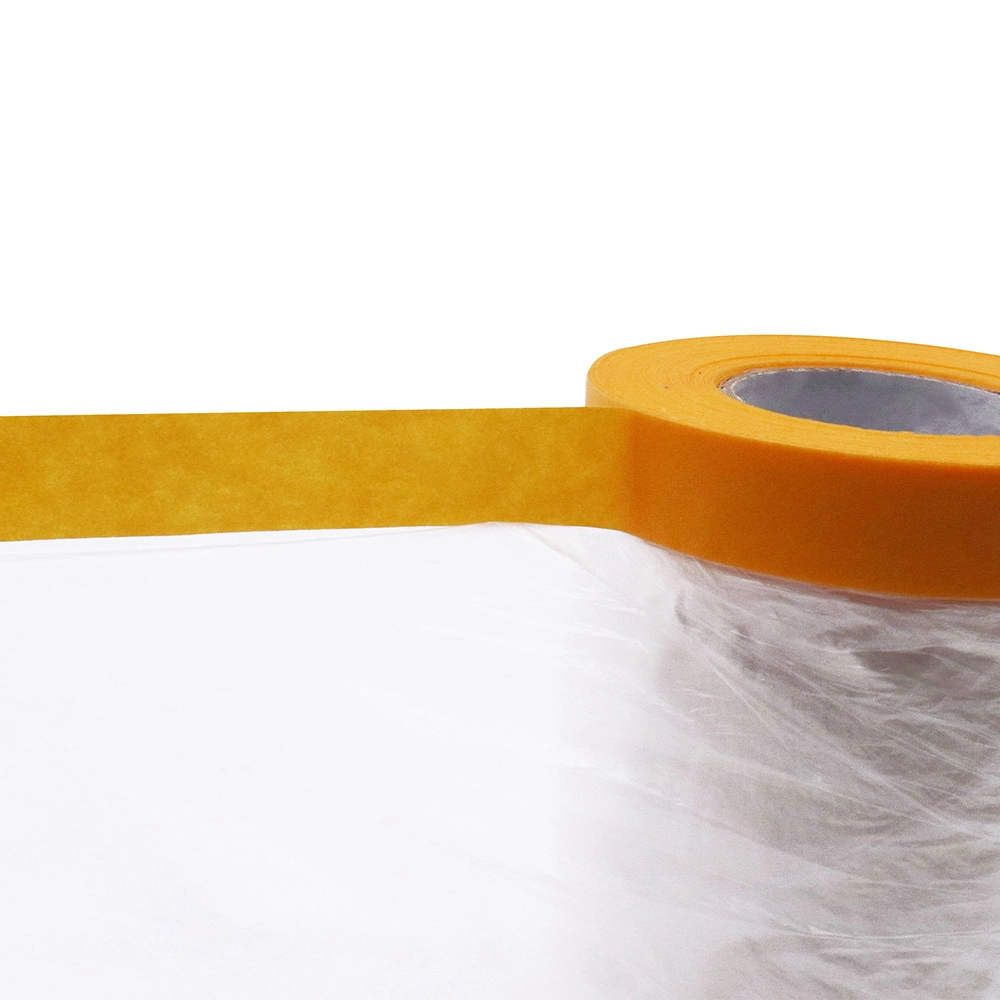

Throughout the entire process of product manufacturing, fabrication, transportation, storage, and installation, preventing surface scratches, dirt, or damage is a challenge that impacts product quality and brand reputation. Our Protective Film is designed to solve this. It is a self-adhesive protective material with a plastic film backing, such as Polyethylene (PE), coated with a special pressure-sensitive adhesive. Its superior weather resistance and residue-free removal allow it to cling to a product’s surface like an invisible “skin,” providing comprehensive protection and ensuring your product arrives at the customer’s hands in the same perfect condition as it left the factory.

Core Advantages & Key Features

- Perfect Surface Protection Our protective film effectively resists scratches, abrasion, dust, dirt, and grease. Whether during fabrication processes like machine stamping and bending, or during long-distance transportation and installation, it provides a reliable physical barrier for smooth surfaces.

- Residue-Free Removal, Never Damages the Surface The film’s adhesive is specially formulated. Even after a long period of use, it will not leave any adhesive residue on the protected surface upon removal, nor will it damage the original gloss or coating. You can simply peel it off to restore the product’s original appearance.

- Customizable Adhesion & Thickness We offer protective films with various adhesion levels, including low, medium, and high tack. You can choose the most suitable tack level based on different surface materials (e.g., glass, mirror-finish stainless steel, brushed aluminum, plastic sheets, or carpets) and the intensity of the fabrication process, ensuring both effective protection and easy removal.

- Strong Weather Resistance, Easy to Process Our protective film has good UV resistance and weather resistance, allowing for short-term outdoor use. It also has excellent stretchability and formability, making it easy to cut, die-cut, and apply, perfectly fitting your automated production line.

Typical Applications

- Metal Sheets: Surface protection for stainless steel, aluminum sheets, galvanized sheets, etc., during processes like stamping, bending, and polishing.

- Plastic Sheets: Scratch prevention for acrylic, PC, PVC, and other plastic sheets during cutting and transportation.

- Furniture & Home Appliances: Anti-scratch and anti-stain protection for the casings of refrigerators, washing machines, cabinets, etc.

- Glass & Carpets: Used to protect windows, mirrors, and floors during renovation and installation.

Client Testimonials & Case Studies

“In our process of manufacturing high-end home appliances, surface scratches were our biggest quality control challenge. After using this protective film, our products are perfectly protected during assembly and transportation. Now, our rework rate has significantly dropped, and customer complaints are almost zero. This has not only saved us costs but also greatly enhanced our brand image.” — Quality Manager, a home appliance manufacturer

Frequently Asked Questions (FAQ)

- Q: How should I choose the right adhesion level? A: The choice of adhesion depends on the smoothness and roughness of the protected surface. The smoother the surface, the lower the adhesion required; the rougher the surface, the higher the adhesion needed. We recommend conducting a small-scale test before mass use to find the best match.

- Q: What is the difference between protective film and stretch wrap? A: The difference is in their adhesion and purpose. Protective film has an adhesive and sticks directly to the product’s surface to prevent surface damage. Stretch wrap has no adhesive and primarily uses its own tension to wrap and secure goods to prevent them from scattering, typically for pallet packaging.

- Q: Can this protective film be reused? A: No. Protective film is a single-use product. Its adhesion will be significantly reduced after removal and cannot provide reliable protection again.

Reviews

There are no reviews yet.