Unique Advantages of PVC Protective Film

High Tear and Puncture Resistance

Unlike thin PE films that easily tear, our PVC film is engineered to endure abrasion, handling, and stretching without breaking.Controlled Adhesive for Clean Removal

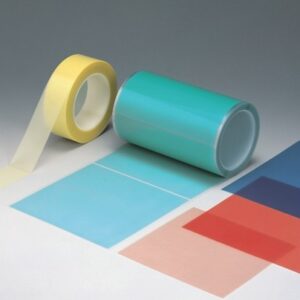

The specially formulated adhesive ensures a secure grip during use but leaves no sticky residue when removed, even after prolonged contact.Optical Clarity & Surface Visibility

PVC film maintains surface visibility, allowing for inspection and quality control without removing the protective layer.Environmental and Chemical Resistance

Resistant to moisture, dust, mild chemicals, and UV exposure, protecting sensitive surfaces under demanding industrial conditions.

Technical Specifications

| Feature | Detail |

|---|---|

| Material | High-Grade PVC |

| Thickness | 40–200 μm (customizable) |

| Width | 100–2000 mm |

| Length | 50–1000 m per roll |

| Adhesive | Low-to-medium tack, residue-free |

| Surface | Smooth or textured finish |

| Temperature Range | -10°C to 70°C |

Custom sizes, thicknesses, and adhesive strengths are available upon request.

Real-World Applications

Automotive Manufacturing: Protects painted body panels, trim, and interior components during assembly and transport.

Electronics & Appliances: Shields glossy surfaces, metal, and coated plastics from scratches and dust.

Glass & Furniture: Maintains scratch-free surfaces for mirrors, tempered glass, and lacquered wood.

Industrial Components: Ideal for metal sheets, profiles, and custom-machined parts that require safe handling.

Why Professionals Trust Our PVC Protective Film

Decades of Industry Experience: Developed in collaboration with surface protection specialists for precise performance.

Tested and Certified: Meets ISO and IEC standards for adhesion, tear resistance, and chemical stability.

Custom Solutions: We work with clients to tailor thickness, adhesive, and film type to each application.

Global Use: Trusted by manufacturers in Europe, North America, and Asia for high-value products.

Ordering Information

Minimum Order Quantity (MOQ): 500 rolls, adjustable by specification.

Delivery: Fast production and shipping globally.

Customization: Thickness, width, adhesive, and surface texture tailored per client needs.

Conclusion

When product surfaces matter, compromise is not an option. Our PVC protective film offers a balance of strength, clarity, and clean adhesion that ensures surfaces stay pristine from production to installation.

Request a sample or discuss your custom specifications today to experience industry-grade surface protection.

Reviews

There are no reviews yet.