Core Advantages & Key Features

- High-Efficiency Heat Transfer, Superior Performance Made with high-thermal-conductivity materials, it establishes a stable heat transfer bridge between the heat-generating component and the heat sink. This ensures heat is efficiently and continuously drawn away from the core components, significantly lowering the device’s operating temperature and enhancing product performance and reliability.

- Simplified Assembly, Replaces Traditional Methods As a solid-state thermal interface material, it completely replaces cumbersome screws, clips, or messy thermal grease. With a simple application, you can accomplish both thermal transfer and fastening tasks, dramatically reducing assembly time and cutting production costs.

- Strong Adhesion, Long-Lasting Reliability The tape’s adhesive layer provides strong peel and shear strength, securely fastening heat-generating components (like chips, LED lights) to the heat sink. It effectively resists vibration and impact, ensuring the long-term stability of the heat transfer path.

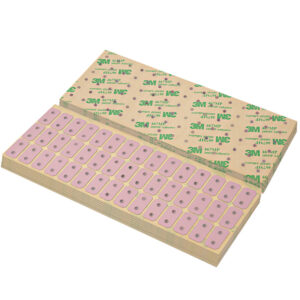

- Flexible and Conformable for Versatile Use The tape has excellent flexibility and conformability, easily filling tiny air gaps and uneven surfaces to maximize heat transfer. It can be die-cut to fit various shapes and sizes, perfectly adapting to different components.

Technical Specifications

Base Material: Thermally conductive polymer or silicone

Adhesive: High-temperature acrylic or silicone adhesive

Thickness: 0.05mm – 1.0mm

Width: 3mm – 1000mm (customizable)

Thermal Conductivity: 1.0 – 5.0 W/m·K

Temperature Resistance: -40°C ~ +300°C

Color: White / Transparent

Typical Applications

- LED Lighting: For bonding and heat dissipation of LED chips to heat sink substrates.

- Consumer Electronics: For bonding and heat transfer between CPUs, GPUs, memory chips, and heat sinks.

- Appliance Manufacturing: For heat dissipation and fastening of power modules and amplifier components to enclosures.

- Communication Equipment: For thermal management in network routers, switches, and other devices.

Client Testimonials & Case Studies

“In our product designs, heat dissipation was always a challenge. We tried screws and thermal grease, but they couldn’t meet our demands for production efficiency and space. This thermal conductive tape solved all our problems. It not only increased our assembly line speed by 30%, but the thermal performance was even better than our traditional methods.” — Production Director, Electronics Manufacturing Company

Frequently Asked Questions (FAQ)

- Q: Can thermal tape completely replace thermal grease? A: It can in many applications. For most low to mid-power electronic components, thermal tape provides sufficient thermal performance while simplifying assembly. For high-power scenarios that require extreme heat dissipation, thermal grease or specialized thermal pads may be more suitable.

- Q: How do I choose the right thermal conductivity? A: Higher thermal conductivity means better heat dissipation. You should choose based on the power density and operating temperature requirements of the heat-generating component. Generally, components with higher power density require tape with a higher thermal conductivity.

- Q: What precautions should I take during use? A: Ensure the bonding surface is clean, dry, and free of oil. Apply uniform pressure during application to ensure full contact between the tape, the heat-generating component, and the heat sink.

Reviews

There are no reviews yet.