In modern electronic designs striving for miniaturization and high integration, every micron of space is critical. Traditional thermal conductive tapes with a backer or thermal pads can add thermal resistance due to their thickness, affecting heat dissipation efficiency. Our Unsupported Thermal Conductive Tape is an innovative material designed to resolve this conflict. By removing the traditional substrate, it is composed of only a highly conductive adhesive layer, forming a flexible, compressible, solid “thermal adhesive.” This allows it to directly bond a heat source to a heat sink, creating the shortest and most direct thermal path possible with the lowest thermal resistance. It is the ultimate solution for space-constrained applications.

Core Advantages & Key Features

- Backerless Design for Minimal Thermal Resistance The biggest advantage of this product is its unsupported structure. It eliminates the thermal resistance caused by heat transfer between different material interfaces, ensuring the heat path from the source to the heat sink is the shortest and most direct possible, thereby achieving the highest heat dissipation efficiency.

- Superior Adhesive Strength for Long-Term Reliability Despite having no backing, this tape still provides powerful adhesive strength. Its special formulation allows it to securely fasten a heat-generating component to a heat sink, effectively resisting mechanical vibration and impact, and ensuring the thermal conduction path remains stable for the product’s entire lifespan.

- Excellent Flexibility and Compressibility The backerless structure gives the tape exceptional flexibility. It can conform like a fluid to fill tiny air gaps and uneven surfaces, ensuring 100% effective contact between the heat source and the heat sink and eliminating thermal resistance caused by poor contact.

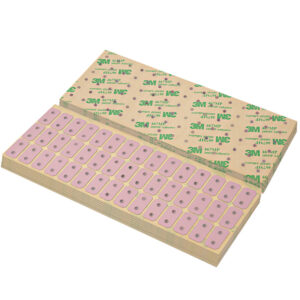

- Ultra-Thin Design, Perfect for Low-Profile Applications Our unsupported thermal tape can be made incredibly thin, with a total thickness as low as 0.1mm. This makes it an ideal choice for high-density, low-profile designs, such as bonding memory chips to heat sinks or for thermal management in LED modules.

Technical Specifications

| Product Code Technical Parameters | KN8105 | KN8110 | KN8115 | KN8120 | KN8125 | KN8130 | KN8138 | KN8140 | KN8150 |

| Color | White | White | White | White | White | White | White | White | White |

| Total Thickness[mm] | 0.05 | 0.1 | 0.15 | 0.2 | 0.25 | 0.3 | 0.38 | 0.4 | 0.5 |

| Adhesive | Acrylic | ||||||||

| 180°Peel Strength[N/inch] | 12 | 12 | 12 | 15 | 15 | 18 | 18 | 18 | 18 |

| Initial Adhesion[#] | 2 | 3 | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| Retentivity [hour] | 48 | ||||||||

| Thermal Conductivity[W/mk] | 0.3~0.8 | ||||||||

| Long-Term Temperature Resistance[℃] | 80 | ||||||||

| Short-Term Temperature Resistance[℃] | 120 | ||||||||

Typical Applications

- LED Lighting: For bonding and heat dissipation of high-power LED chips to aluminum substrates.

- Consumer Electronics: For ultra-thin bonding and thermal transfer between chips like CPUs, memory, and GPUs to the chassis in smartphones and tablets.

- Component Fastening: For bonding heat-generating electronic components, such as IC chips and diodes, to heat sinks or metal bases.

- Power Modules: For tight bonding and heat dissipation between power components and heat sinks inside the module.

Client Testimonials & Case Studies

“Our LED light fixture design demands extreme compactness and thinness. Traditional thermal materials always added some thickness, affecting our design goals. The introduction of this unsupported thermal tape completely solved our problem. It provides enough adhesive strength while achieving a level of thermal efficiency we’ve never seen before, making our products more competitive in the market.” — Thermal Design Engineer, a well-known lighting company

Frequently Asked Questions (FAQ)

- Q: What is the main difference between unsupported and supported thermal tape? A: Unsupported tape has no middle layer, and heat is conducted directly through the thermal adhesive, resulting in lower thermal resistance. Supported tape has a backing (e.g., glass fiber cloth) between the adhesive layers, which provides higher mechanical strength but adds extra thermal resistance.

- Q: How is unsupported thermal tape applied? A: Our product typically comes with a release liner. Simply peel off the liner, apply the tape to the bonding surface, and then press the component onto the other side with even pressure to secure it.

- Q: Is its adhesive strength sufficient for heavy components? A: Yes, it is designed for permanent bonding. When selecting, you can refer to our technical specifications, such as peel adhesion, based on the component’s weight and size to choose the most suitable model.

Reviews

There are no reviews yet.