Product Description

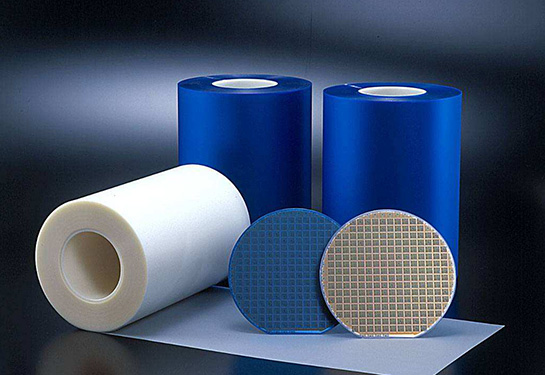

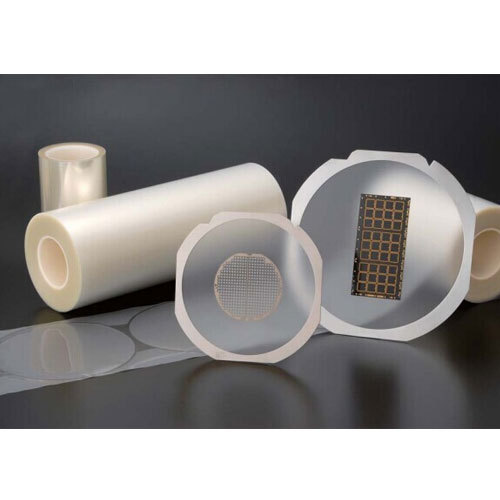

UV release protective film is a high-performance PET-based tape coated with special UV-curable acrylic adhesive. Before exposure, it provides strong adhesion for secure fixing; after UV irradiation, adhesion drops dramatically, allowing easy removal without residue. This film is widely used in semiconductor wafer processing, FPCB manufacturing, LCD/OLED panel protection, and other precision electronic applications where accurate positioning and efficient processing are required.

Specifications

| Product Code Technical Parameters | KA4640 | KA4611 | KA4662 | KA4616 | KA4618 |

| Color | Translucence | Translucence | Translucence | Translucence | Translucence |

| Total Thickness[mm] | 0.08 | 0.11 | 0.155 | 0.16 | 0.16 |

| Backing Thickness[mm] | 0.05 | 0.1 | 0.14 | 0.14 | 0.14 |

| Backing | PET | PET | PO | PO | PO |

| Adhesive | Acrylic | Acrylic | Acrylic | Acrylic | Acrylic |

| 180°Peel Strength (Before UV )[N/inch] | 20 | 8 | 12 | 10 | 20 |

| 180°Peel Strength (After UV )[N/inch] | 0.05~0.1 | 0.03~0.06 | 0.15~0.25 | 0.3~0.5 | 0.05~0.1 |

| UV Exposure Rate[mJ/cm2] | 300~500mJ | 300~500mJ | 300~500mJ | 300~500mJ | 300~500mJ |

| Application | Glass | Glass | MEMS CHIPS | Ceramics | wafer |

Features

Rapid adhesion reduction after UV exposure for efficient release

Stable adhesion and accurate positioning without surface damage

High transparency for optical inspection and automated production

Anti-static treatment to minimize dust contamination

Excellent heat and chemical resistance for precision processes

Applications

Semiconductor wafer dicing and chip processing

FPCB (Flexible Printed Circuit Board) handling and processing

LCD and OLED glass panel protection

Optical components and touchscreen manufacturing

Precision electronic parts transport and surface protection

Reviews

There are no reviews yet.