Surface Protection Solutions for Industrial Applications

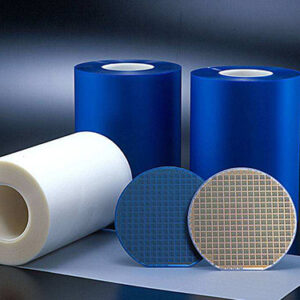

Surface Protection Product Types

Surface protection refers to the use of protective tapes, films, and materials that temporarily shield surfaces from damage during industrial operations. These solutions help maintain product quality and reduce rework or replacement costs.

Surface protection products are widely used across automotive, electronics, metal fabrication, construction, and appliance manufacturing industries.

Benefits of Industrial Surface Protection

- Prevents scratches, dust, and surface contamination

- Reduces damage during manufacturing and logistics

- Improves final product appearance

- Minimizes rework and warranty claims

- Ensures clean and residue-free removal

Industries & Applications

- Automotive manufacturing and transportation

- Metal fabrication and stainless steel processing

- Electronics and appliance production

- Glass, plastic, and aluminum surface protection

- Construction materials and installation

Surface Protection FAQ

Surface protection materials are used to prevent scratches, dust, abrasion, and damage during:

Manufacturing

Transportation

Storage

Installation

They are widely applied to protect metal, plastic, glass, painted surfaces, and decorative panels.

Our surface protection tapes and films work well on:

Stainless steel & aluminum sheets

Painted metal panels

Plastic boards (PMMA, PVC, PC)

Glass & mirrors

Automotive parts and trim

Electronics housings

We offer different adhesive systems to match smooth, textured, or coated surfaces.

No. Our products are designed for clean removal without adhesive residue, even after long-term protection.

For sensitive surfaces, we recommend low-tack options and testing before full-scale use.

Depending on the material and environment, surface protection can typically remain for:

30–90 days indoors

Up to 6 months under controlled storage

For outdoor UV exposure, we provide UV-resistant protection films.

Surface protection tape/film is designed for long-term physical protection, while masking tape is mainly used for temporary paint masking.

Surface protection focuses on:

Scratch resistance

Impact protection

Clean peel-off over longer periods

Yes. We provide full OEM/ODM customization, including:

Thickness (30–150 microns or more)

Width and roll length

Adhesion level (low / medium / high tack)

Printing with logos or handling instructions

Customization ensures the best balance between protection and easy removal.